The Useful Machine

Team: Oliver, Carlotta, Manuja, Carmen and me.

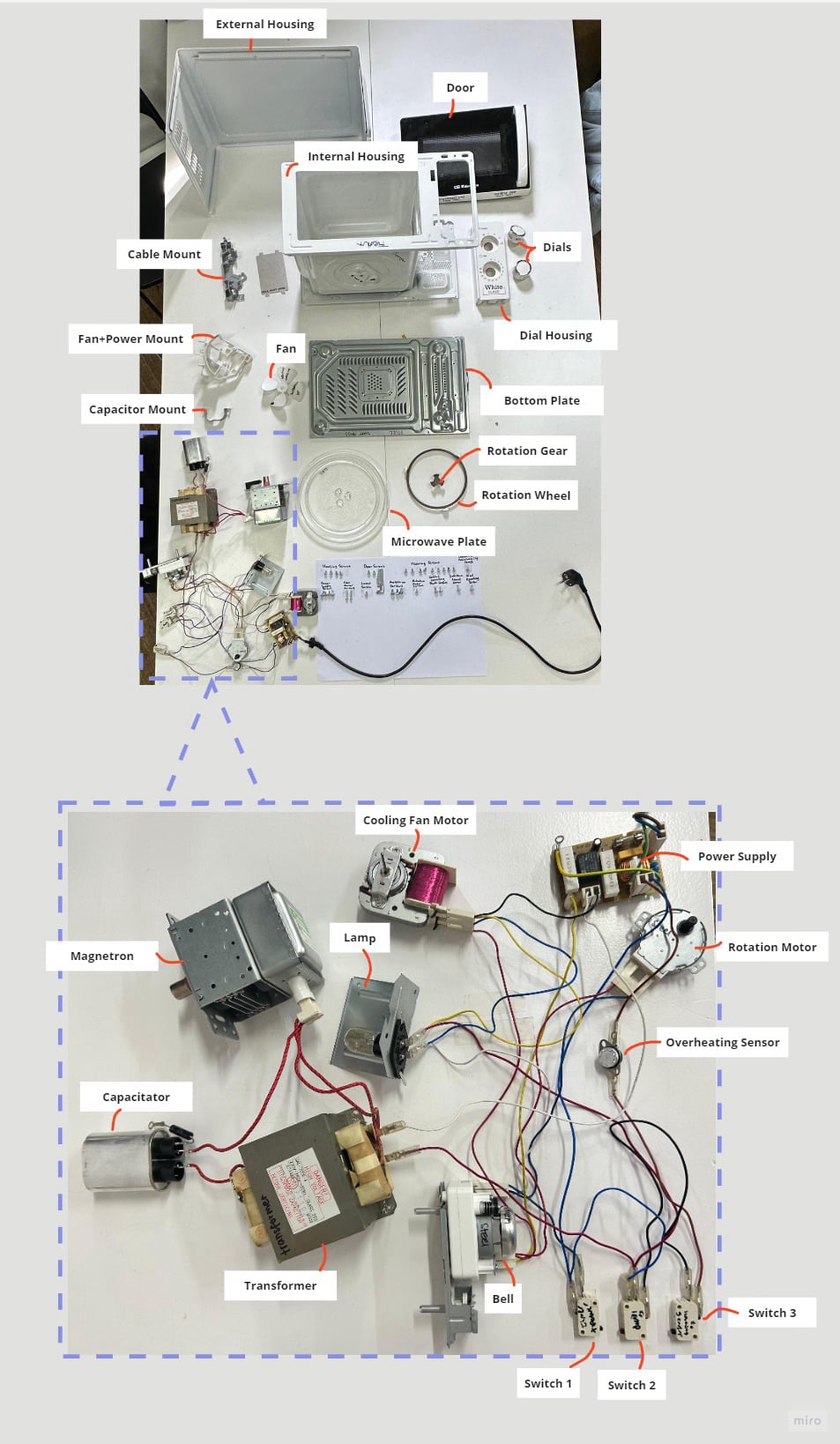

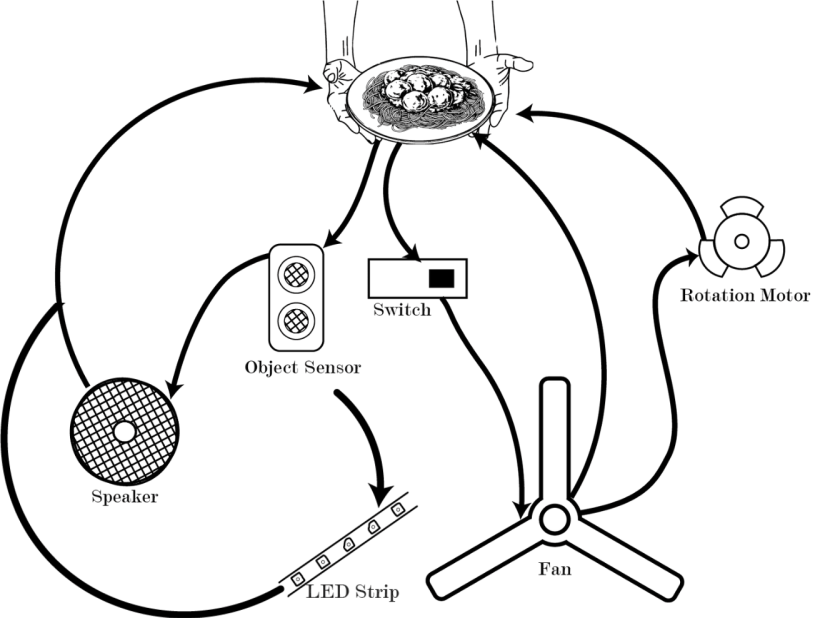

The first exercise consisted in dismantling a broken machine and creating a forensic study for each of its electronic component, testing whether they worked to identify the faulty component(s). Our team chose an old microwave that did not work when plugged into a power source.

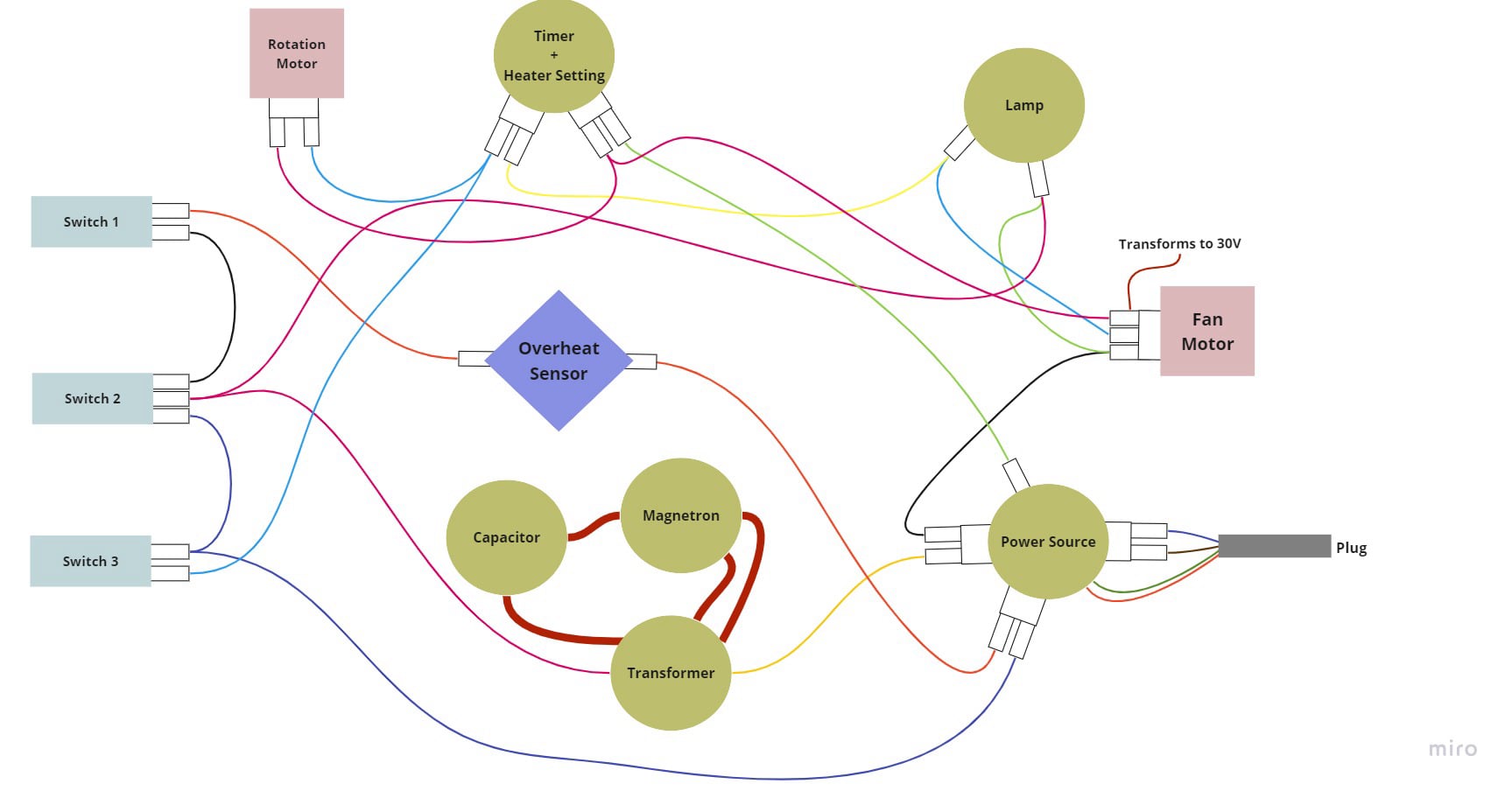

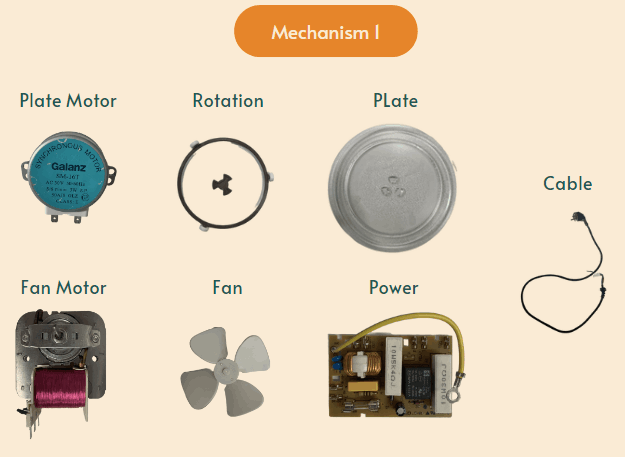

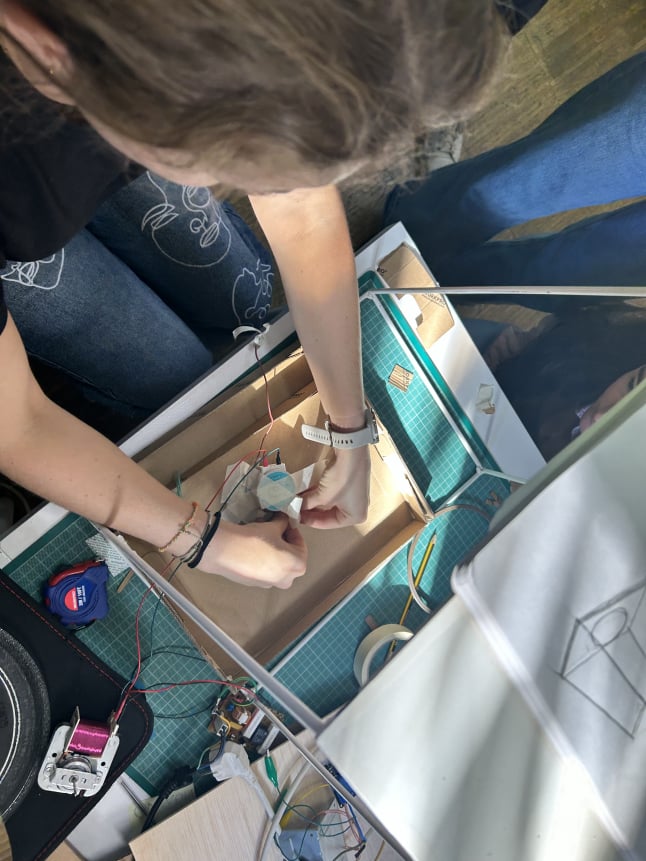

Once all electrical parts were carefully disconnected, they were then individually repowered with an external power source and reconnected to identify the relationship between each component and recreate the circuit.

Surprisingly all the components were AC instead of DC, which means we had to plug components into the wall, ensuring sufficient security measures. Most components functioned at 240-250V, except the plate rotation motor which functioned at 30V.

All the pieces that we tested were working. We therefore concluded that the transformer and/or capacitor and/or the microwave emitter were the faulty pieces causing the microwave not to function, as these were the only untested components due to safety considerations.