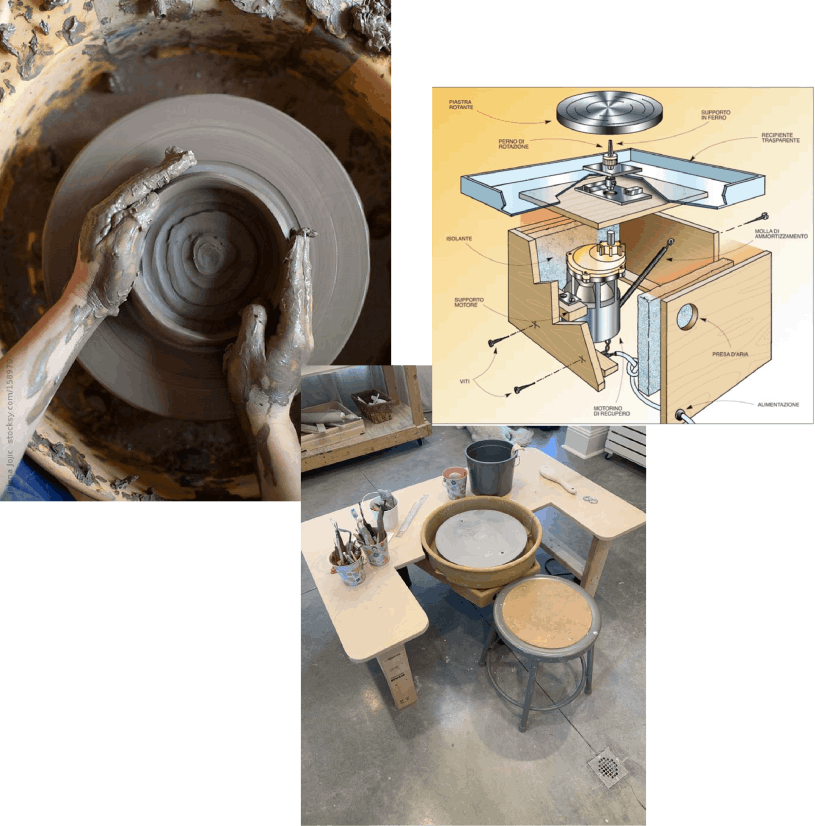

Initial Concept

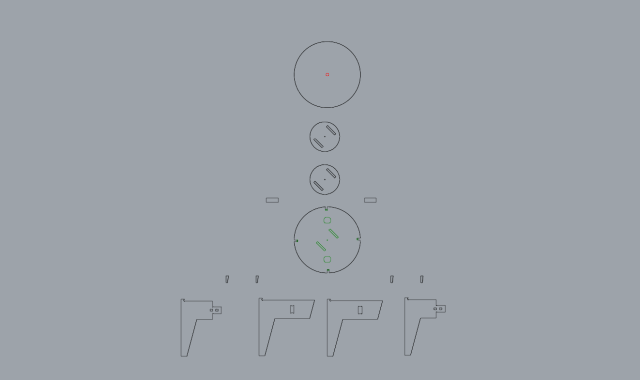

Our team started with an ambitious project: designing an electric pottery wheel for classroom use. However, due to the lack of a powerful motor, we switched to creating a manual spinning table. This shift required us to rethink our design while maintaining the goal of functionality and usability. We decided to match the table's height with a seat another group had made, ensuring compatibility and practicality. We brainstormed and decided on a central threaded bar for the table's rotation, supplemented by small wheels on opposite sides for added stability. This combination ensured smooth and balanced spinning.